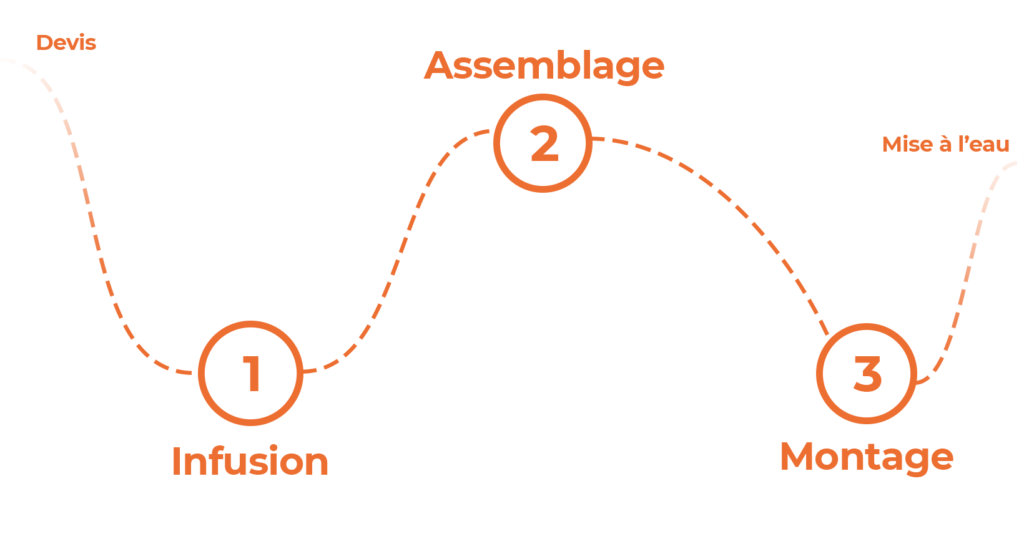

Five steps from dream to purchase

Our yachts are built by hand, in a traditional way, according to a five-step process: elaboration of the estimate with the client, infusion of the different parts, assembly, fitting, and shipping.

Step 1: Quote and customisation

The design of the boat starts with its configuration by the customer himself: with the help of the shipyard, he chooses his options according to his sailing programme to optimise the future boat.

Everything is done in collaboration with the shipyard, via a configurator that allows you to see the total price of the boat in real time according to the options chosen, which allows for great precision in the choice!

Step 2: Infusion

In order to build the boat, the following parts must first be made: the hull with its structural grid, the deck and its counter-mould, the interior modules and all the small composite parts (rudders, steering, etc.). The infusion process allows the creation of light, homogeneous, very rigid and long-lasting composite parts. The JPK team has mastered this technique perfectly.

The process consists of three steps.

First, the various tissues (fibreglass) and the PVC foam core are placed in the mould, dry. The entire structure is then vacuumed before the resin is injected into it. Finally, everything is stripped off after 24 hours of drying, and the assembly can begin, directly in the mould.

Under vacuum, the materials are perfectly compacted, resulting in a lower rate of resin impregnation in the fabric from 60 to 38% and an elimination of air micro-bubbles in the fibers (the origin of osmosis problems): this ensures perfect homogeneity of the sandwich.

The structural grid is also infused at the same time as the shell and therefore forms a very rigid one-piece structure.

Step 3: assembly

Once the composite parts are made, it is time to assemble them to form the rigid structure of the boat.

The hull, the deck, the deck counter-mould, and the various modules inside the boat are thus joined together, adjusted to be finely tuned, and then glued: this is the moment when the boat takes its shape.

Step 4: fittings and finition

Fittings is the final stage in the construction of a JPK: it is the installation of all the components needed to make the boat work. Deckware, electronics, electricity, piping, on-board equipment, upholstery ... all this installation starts during assembly, when the different sections of the boat are most accessible.

The fittings also includes the installation of the woodwork and all the finishing and cleaning work to give the customer a perfectly clean boat.

Final stage: departure from the yard and commissioning

At the end of the construction process, the boat is keeled, cleaned, finished and prepared for shipment, and most often launched near the yard to allow the fitting technicians to finalise the work directly on the water.

Finally, with the boat fully equipped, it's time to take the first trip with the client and savour the moment - magic! - while noting the final details that need to be corrected.